Do you know how are LED screens manufactured? Its manufacturing process must be sophisticated and complicated, this blog will try to introduce you from a more concise perspective. If you are interested, please read on!

LED screens are widely used in various fields such as advertising, entertainment, and information display. The manufacturing process of LED screens involves several crucial steps, including chip production, LED packaging, module assembly, and panel fabrication. Here is a brief overview of how LED screens are manufactured:

The first step in manufacturing LED screens is the production of LED chips. This process involves growing a crystal substrate, adding various layers of materials, and creating a p-n junction. Once the chips are manufactured, they are sorted by color, brightness, and voltage.

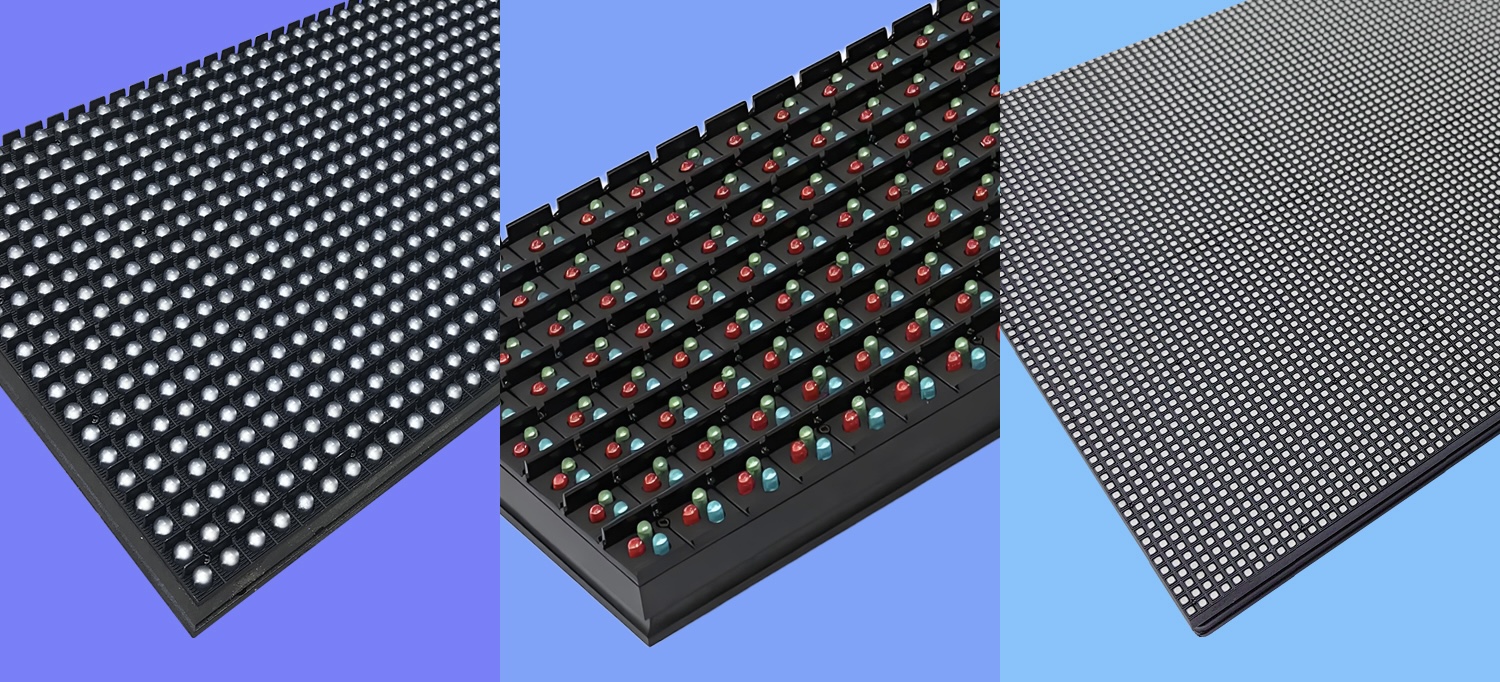

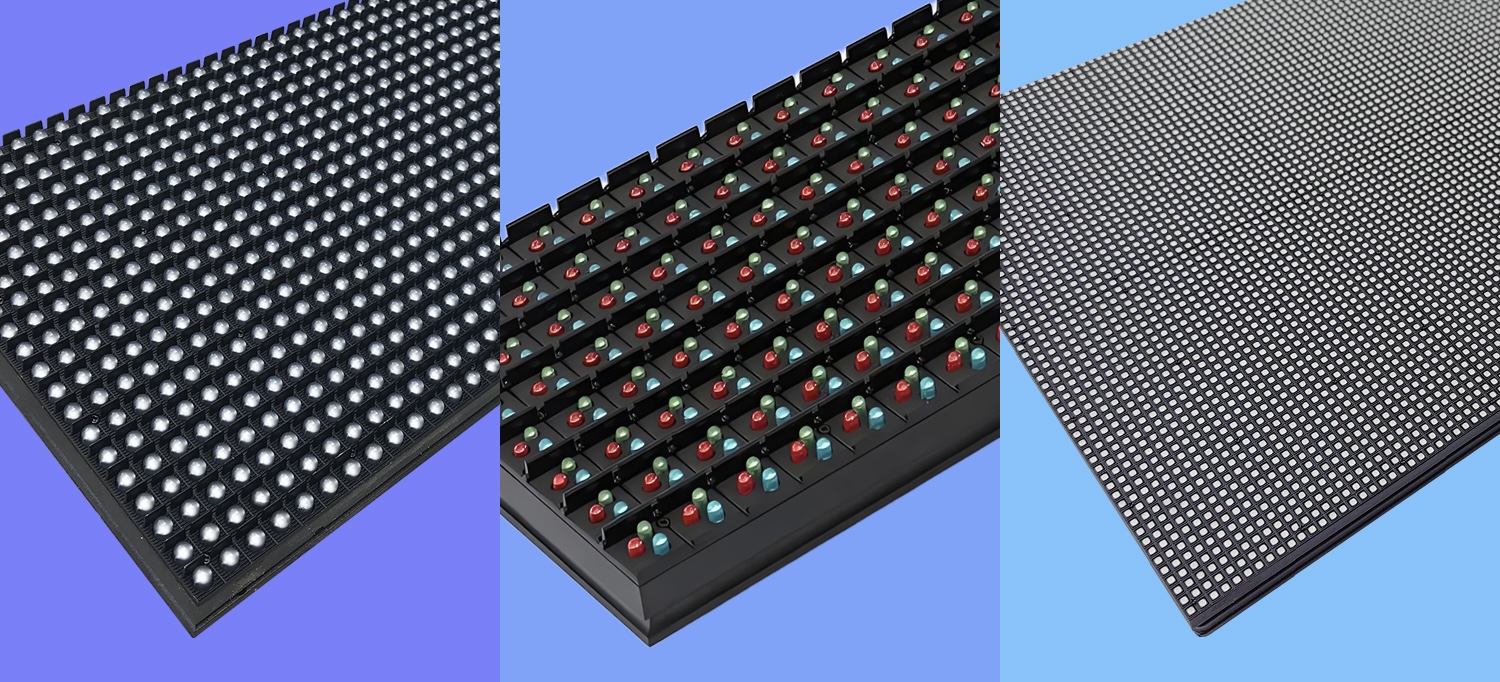

After the chips are sorted, they are then packaged into individual LEDs. This process involves attaching a lead frame and a lens to the chip, encapsulating it in epoxy resin, and finally, testing the LED to ensure it meets the required specifications.

Once the LEDs are packaged, they are assembled into modules. This involves mounting the LEDs onto a printed circuit board (PCB), adding a driver chip, and connecting the modules with ribbon cables.

How are LED screens manufactured? Kingaurora has the answer. It uses DIP570 packaging technology to make its products more powerful.

This technology involves packaging LED chips in a Dual In-line Package (DIP), which has two parallel rows of leads extending from the bottom of the package. The DIP570 package is a popular choice for outdoor LED displays due to its high brightness, wide viewing angle, and excellent heat dissipation.

Benefits of DIP570 encapsulation technology include:

The DIP570 package has a large size, allowing for a greater number of LED chips per module, resulting in higher brightness levels.

The package's design allows for a wide viewing angle, making it suitable for outdoor displays where viewers may be at varying angles to the screen.

The DIP570 package has a metal substrate, which provides excellent heat dissipation, making it ideal for outdoor use in high-temperature environments.

The DIP570 package is easy to repair or replace, as individual LEDs can be easily removed and replaced, minimizing downtime and maintenance costs.

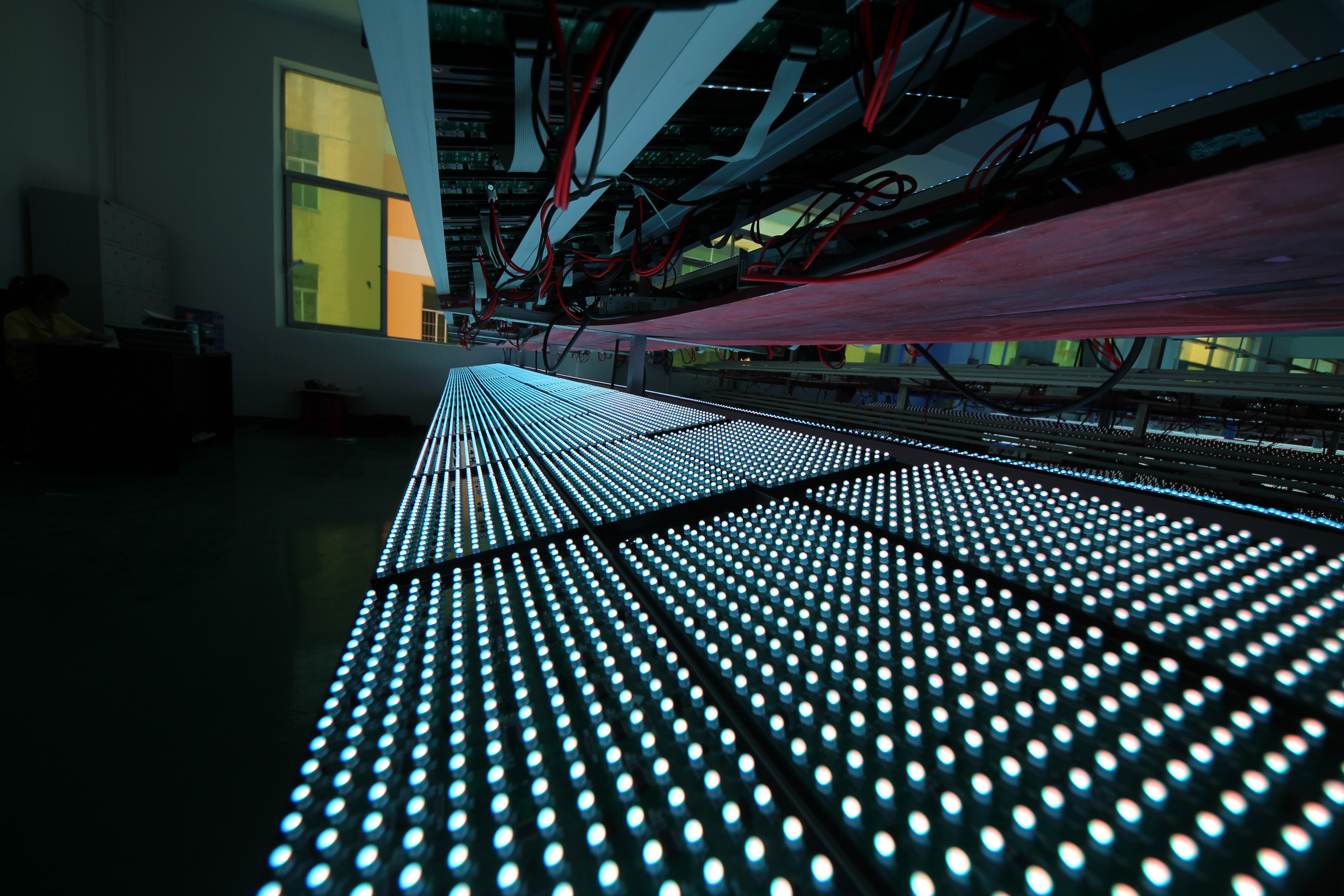

The final step in manufacturing LED screens is the fabrication of the panels. This process involves mounting the modules onto a frame, connecting the modules with power and signal cables, and attaching a cover to protect the screen.

Kingaurora is a reliable LED light source manufacturer that combines packaging and display production lines. There are several reasons why you can trust Kingaurora:

Kingaurora's energy-saving IC and "three colors in one" lamp beads are patented products that offer many advantages, including a smaller color angle, improved image reproduction, lower power consumption, and reduced failure rates.

With over 30 years of experience in DIP lamp development, Kingaurora produces high-quality products that have been verified by the market. Their products have a wide viewing angle and excellent color consistency, resulting in superior image quality.

Kingaurora has its own full production line production base, covering an area of 12,000 square meters and equipped with 50 imported ASM high-precision production equipment. With an annual production capacity of 50,000 square meters, Kingaurora can ensure high production efficiency and timely delivery.

Kingaurora has a team of 120 professional production personnel who supervise each step of the production process to ensure the highest quality standards are met. Kingaurora strictly follows delivery schedules, ensuring customer satisfaction.

In summary, Kingaurora's innovative technology, high-quality products, advanced production facilities, and professional team make them a trustworthy LED light source manufacturer.

After understanding how are LED screens manufactured, let's find out how to customize your order at Kingaurora. The following is the detailed process:

Kingaurora's team of experts first assesses your needs and requirements to provide you with the best possible solutions that align with your objectives.

They offer a free presale planning service that includes a comprehensive and clear effect map, quick prototyping, and more, allowing you to visualize the final product before placing an order.

Kingaurora's team of professionals designs and develops products tailored to your specific needs and requirements, considering the different usage scenarios to ensure that the product meets your unique needs.

They are committed to strict adherence to deadlines, and the products come with a lifetime warranty. They also offer optional warranties of two years or more, and a dedicated customer service team is available around the clock to assist you with any queries.

Their professional engineers provide remote technical support, training, and guidance, ensuring that you can use products efficiently and effectively. Additionally, for significant projects, they offer on-site support to guarantee that everything runs smoothly.

In Kingaurora, you can find many types of LED screens, such as indoor LED fixed screens, outdoor LED fixed screens, rental LED screens, energy-saving LED displays, solar car LED displays, and light bar screens, etc.

These products are widely used in various places, bringing perfect lighting effects. They are made of the best quality materials and have excellent heat dissipation ability. If you want to buy high-quality products to meet your needs, please come to Kingaurora.

In summary, the manufacturing process of LED screens involves several crucial steps, including chip production, LED packaging, module assembly, and panel fabrication.

Each step is important in ensuring the final product meets the required specifications for color, brightness, and resolution.

Such as the DIP570 encapsulation technology used by Kingaurora provides high brightness, wide viewing angle, excellent heat dissipation, and easy maintenance for outdoor LED displays.

3th Building,Gaosite Zone Pingshan

New District, Shenzhen

sevice88@kingaurora.com

3th Building,Gaosite Zone Pingshan

New District, Shenzhen