In the current LED display industry, technological trends appear to have completely shifted toward SMD (Surface Mount Device). Advantages led by SMD technology, such as smaller pixel pitches, higher resolution, and thinner designs, make it almost the preferred choice for all projects pursuing high-definition display effects. The industry's focus is mostly on next-generation miniaturization technologies like Mini LED and Micro LED.

However, amidst the chorus of pursuit for SMD, we can still hear a voice of insistence. Global high-end display solution provider Kingaurora still firmly retains and continues to develop its proprietary DIP (Dual In-line Package) packaging technology and products in its core product line, such as the market-validated DIP570 series. This is not stagnation, but a focused and necessary technological strategic choice made after deeply understanding the diversified needs of the market. Kingaurora's persistence reveals that in the long river of technological evolution, applicability often holds greater commercial and engineering value than absolute advancement.

To understand Kingaurora's insistence, we must first discard the simple bias that "DIP technology is outdated" and objectively examine the essential differences between the two technologies.

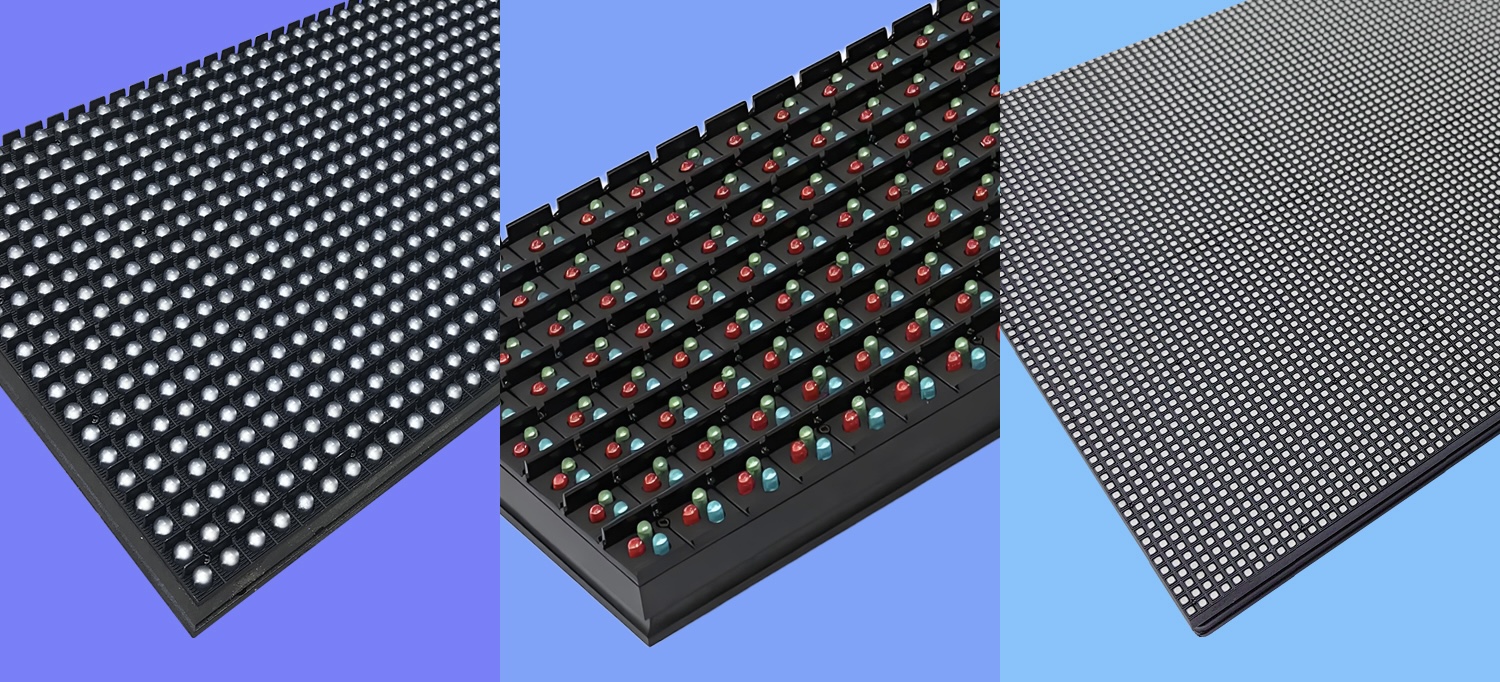

DIP packaging can be popularly understood as "plug-in type." It packages LED chips into independent cylindrical lamp beads with long pins, which are then inserted into the through-holes of the PCB board for soldering, much like plugging in components. This long-established process determines its characteristics: sturdy structure, lamp beads completely encapsulated in resin, and firm pin soldering.

SMD packaging, on the other hand, is "surface-mount type." It directly mounts tiny LED chips onto the surface of the PCB board, with no exposed pins, allowing for very small volumes. This enables more lamp beads to be arranged per unit area, achieving finer images (smaller pixel pitches, such as P4, P2.5).

| Feature Dimension | DIP (Dual In-line Package) | SMD (Surface Mount Device) |

|---|---|---|

| Core Structure | Independent lamp beads with pins, inserted into PCB through-holes for soldering | Pinless micro patches, directly mounted on PCB surface |

| Physical Strength | Extremely high. Resin encapsulation, integrated structure, strong impact and pressure resistance. | Average. Chips and solder joints are directly exposed, vulnerable to external force damage. |

| Protection Level | Inherently excellent. Good sealing, easy to achieve waterproof, moisture-proof, dustproof (IP65 and above). | Relies on subsequent processes like potting for supplementation; basic protection is weaker. |

| Pixel Pitch | Relatively large. Limited by the physical size of lamp beads, currently mainstream at P10 and above. | Very small. Can achieve sub-P2 micro pitch, suitable for high-definition close-range viewing. |

| Heat Dissipation Path | Longer, conducted to PCB through pins. | Shorter, directly conducted through pads. |

| Main Application Scenarios | Long-distance viewing, harsh outdoor environments (road billboards, rooftop大字, stadium scoreboards, etc.). | Medium to close-distance viewing, controlled indoor and outdoor high-definition scenes (commercial advertising, stage rental, command centers, etc.). |

The table clearly shows the fundamental difference: DIP's core advantage lies in ultimate reliability and environmental tolerance, while SMD's core advantage lies in display precision. Their relationship is not simply "new replacing old," but each has an irreplaceable mission on different application battlefields.

Kingaurora's insistence on proprietary DIP packaging is precisely based on deep insight into a series of "rigid demand markets." The primary requirement for display equipment in these markets is often not "seeing finely," but "being visible under any circumstances" and "long-term stability without problems."

In desert areas of Saudi Arabia, summer temperatures exceed 50°C, ground temperatures can reach over 70°C, accompanied by frequent sandstorms. In coastal cities of India or Southeast Asia, the air is filled with highly corrosive salt fog. In frigid zones near the Arctic Circle, temperatures may remain below -30°C for extended periods. In these places, a display screen is first an "industrial device," and only secondarily a "display device."

Kingaurora's proprietary DIP packaged products, such as solutions designed for high-temperature deserts, use special anti-UV, high-temperature-resistant epoxy resin materials for the lamp beads, with internal structures optimized to cope with severe thermal expansion and contraction. The sturdy physical packaging itself is the first and most reliable line of defense against sand, salt fog, and rain erosion. This reliability design starting from the component level is unmatched by later protective measures.

Beside highways, atop stadiums, or on the exterior walls of high-rise buildings, viewing distances often range from tens to hundreds of meters away. At this point, the human eye the fineness difference between P6 and P10. The key demand is: under intense sunlight, is the image still clear, bright, and color-saturated?

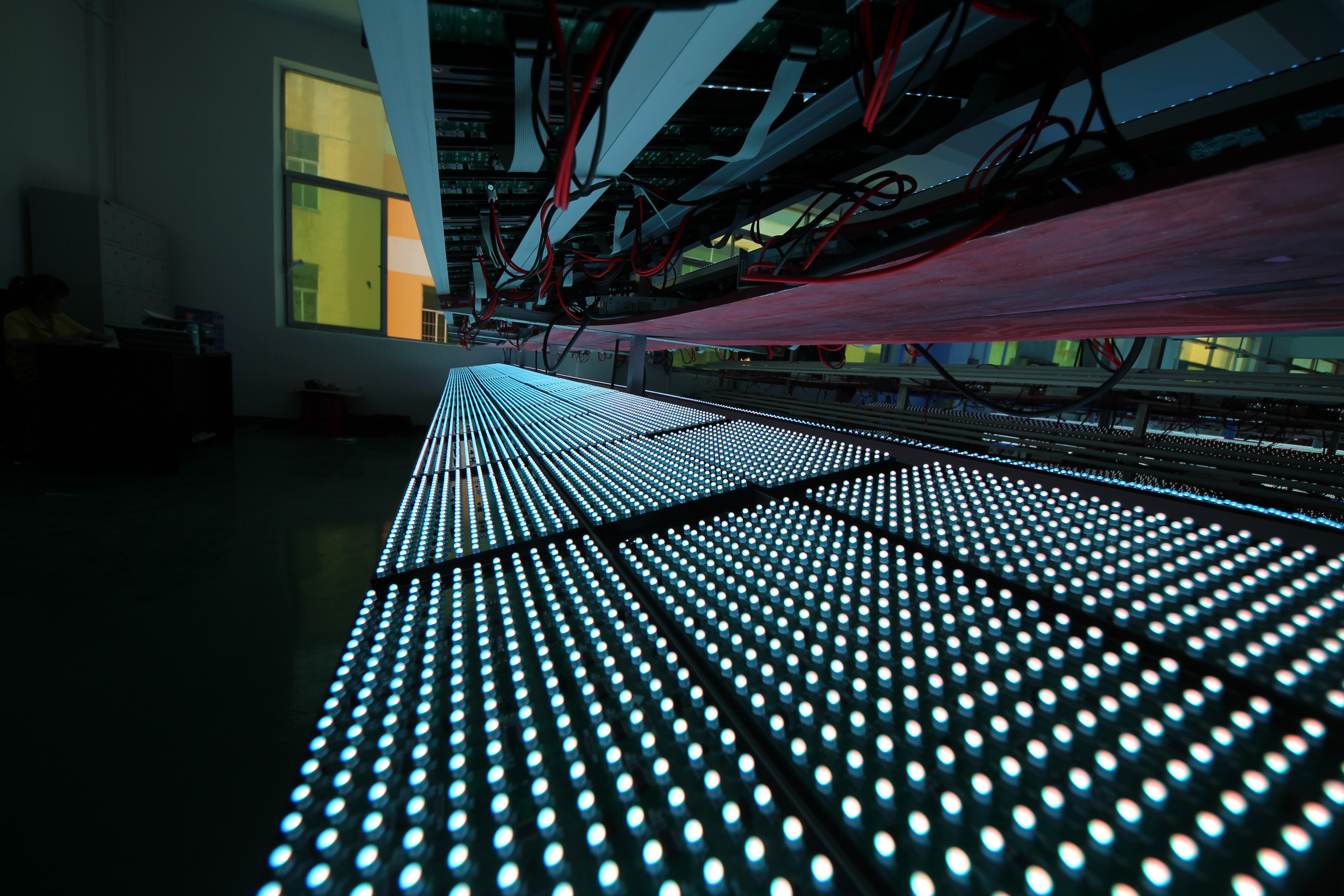

Due to its independent lamp cup structure, DIP packaging inherently has better light concentration than SMD, more efficiently projecting light energy directly forward, achieving higher axial brightness (usually over 10,000 nits), with slower light decay. Through its proprietary packaging process, Kingaurora can precisely control the optical curve and brightness consistency of the lamp beads, ensuring excellent visual performance at long distances. For long-distance signage, excessively high resolution is a pointless cost waste, while insufficient brightness is a fatal flaw.

For rooftop or large outdoor billboards installed dozens of meters high, each maintenance operation. One of the owner's most concerned metrics is "mean time between failures."

Due to the pluggable characteristic of individual lamps (although modern maintenance mostly uses modules) and, DIP displays, when correctly installed, can easily achieve 8-10 years or even longer of stable operation with. Through proprietary packaging, Kingaurora can manage the supply chain and quality control across the entire chain, ensuring the longevity consistency of each DIP lamp bead. Minimizing the total cost of ownership throughout the entire lifecycle (including initial cost, energy consumption, maintenance, replacement) is the economic account that many large projects value more.

Insisting on using DIP is one thing, but insisting on "proprietary" DIP packaging is the key to Kingaurora elevating this choice into a core competitive advantage.

General-purpose DIP lamp beads may meet ordinary needs but cannot. Kingaurora can conduct customized R&D in encapsulation gel ratio, bracket materials, chip selection, and optical design according to specific project requirements (such as Saudi Arabia's heat or Northern Europe's extreme cold), creating "targeted treatment" solutions.

Proprietary packaging means full process control from chip sourcing, packaging production to aging testing. Kingaurora can perform more stringent reliability tests than general industry standards (such as thermal shock tests, salt spray tests), ensuring each batch of products meets promised lifespan and performance indicators. This direct control over quality is unachievable with OEM or purchased lamp beads.

In the long term, proprietary packaging after forming scale in specific niche markets. More importantly, it avoids dependence on上游供应商 for critical components, ensuring product delivery stability and technological iteration autonomy.

Kingaurora's insistence on proprietary DIP packaging teaches us a vivid "technology selection lesson." It tells us that the value of technology lies not in whether it is the "newest" or "trendiest," but in whether it is the most "suitable."

In indoor and outdoor scenes pursuing and visua, SMD and Mini/Micro LED are undoubtedly kings. But in those "heavy-duty" fields concerning safety, requiring 7x24-hour endurance of, and pursuing, deeply optimized and independently innovated DIP technology remains the undisputed king.

Kingaurora's insistence is not resistance to technological;—applying the most suitable technology, with the highest quality and deepest customization, to the scenarios that need it most. This pragmatic innovation based on market demand rather than technological trends may be the fundamental reason why enterprises can and continuously win customer trust. In the vast display market, there are both, and Kingaurora

https://www.linkedin.com/pulse/why-dip-outdoor-led-displays-better-than-smd-3d-led-display-zgxrc

3th Building,Gaosite Zone Pingshan

New District, Shenzhen

sevice88@kingaurora.com

3th Building,Gaosite Zone Pingshan

New District, Shenzhen