LED display technology has made significant progress over the past few decades, with packaging technology being a key factor determining LED performance, reliability, and application scenarios. DIP (Dual In-line Package) and SMD (Surface Mount Device) are two mainstream LED packaging forms. This article provides a detailed analysis of the differences between DIP570, DIP346, and SMD beads in terms of packaging methods, characteristics, and application scenarios to help readers better understand and select suitable LED products.

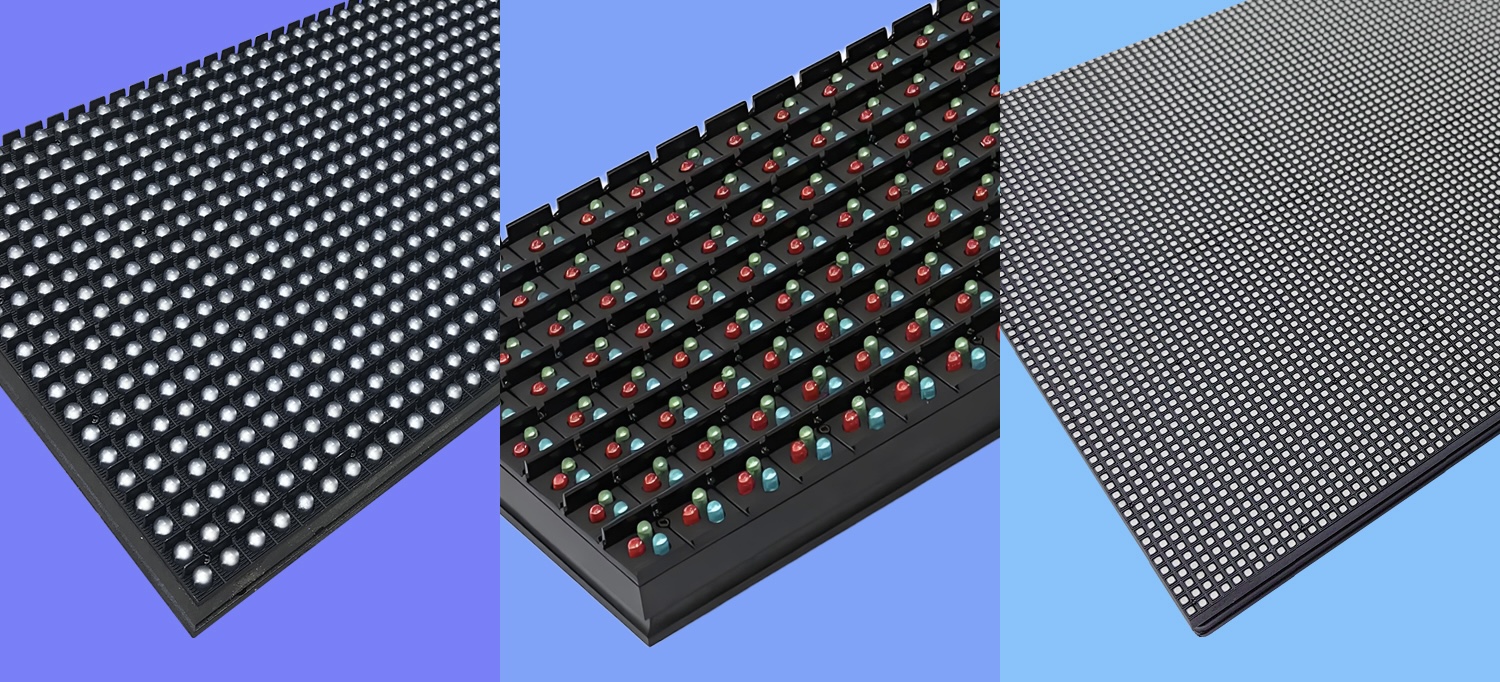

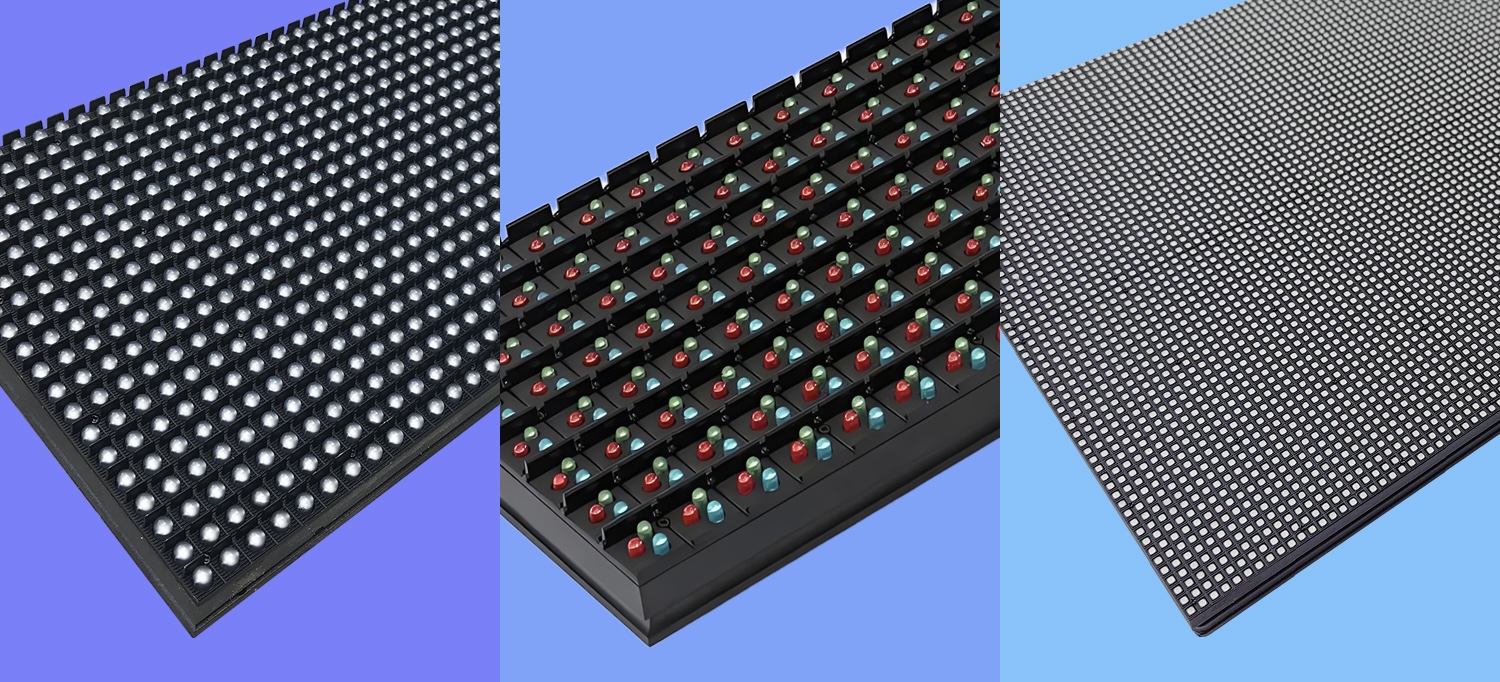

The DIP570 belongs to the dual in-line package (DIP) category, with a core structure based on a metal bracket: the light-emitting chip is fixed in the bracket's "reflector cup," which concentrates light through optical design. The exterior is filled with high-temperature resistant epoxy resin, which both protects the chip from dust and moisture erosion and improves light output efficiency. After packaging, the bead extends two metal pins with a diameter of approximately 0.5mm at the bottom, with overall dimensions of about 5.0mm×7.0mm×3.0mm (length × width × height). The appearance is either "flat-top" or "bullet-head" shaped. During installation, the pins need to be inserted into the through-holes of the PCB board and soldered, providing strong mechanical fixation.

The DIP346 is a miniaturized version of the DIP570, with packaging dimensions of 3.0mm×4.6mm. Despite its smaller size, it retains the basic structural characteristics of DIP packaging. The DIP346 also uses a dual in-line design with two pins, but its smaller size allows for higher pixel density in limited spaces, making it suitable for applications requiring finer display effects.

SMD (Surface Mount Device) beads adopt a completely different packaging concept. Unlike DIP's through-hole installation method, SMD beads are directly soldered to the surface of the PCB board using surface mount technology. SMD packaging typically consists of an LED chip, plastic bracket, gold wire connections, and silicone encapsulation. Its pins do not pass through the circuit board but are distributed in the form of metal pads at the bottom of the package, connecting to the PCB board through reflow soldering process. SMD packaging comes in various forms, with sizes ranging from as small as 0201 (0.6mm×0.3mm) to as large as 5050 (5.0mm×5.0mm).

|

Characteristic |

DIP570 |

DIP346 |

SMD |

|

Package Size |

5.0mm×7.0mm |

3.0mm×4.6mm |

Various sizes (e.g., 2835, 5050, etc.) |

|

Installation Method |

Through-hole |

Through-hole |

Surface Mount |

|

Heat Dissipation |

Average |

Average |

Excellent |

|

Power Density |

Lower |

Lower |

High |

|

Production Process |

Relatively Simple |

Relatively Simple |

Highly Automated |

|

Reliability |

High |

High |

Relatively High |

|

Cost |

Low |

Medium |

Varies by size and application |

Due to its larger size and higher single-bead brightness, DIP570 beads are traditionally widely used in outdoor full-color displays, traffic signal screens, landscape lighting, and other fields. Their sturdy structure and good reliability make them suitable for use in harsh weather conditions. The DIP570 products in Kingaurora's series are particularly suitable for outdoor billboards and large displays that require high brightness and long-distance visibility.

As a miniaturized version of DIP570, DIP346 is suitable for indoor and outdoor displays requiring higher pixel density, such as station information screens and shopping mall advertising screens. Its smaller size enables displays to achieve higher resolution while retaining the good reliability and high brightness of DIP packaging.

With their small size, high-density integration, and wide viewing angles, SMD beads have become the mainstream choice for modern LED lighting and display applications. SMD technology is widely used in TV backlighting, indoor lighting, indoor full-color displays, mobile phone flashlights, and other fields. Particularly for small-pitch LED displays, almost all use SMD packaging technology.

With the continuous advancement of LED technology, packaging technology is also evolving. Due to inherent size limitations and narrower viewing angles, DIP packaging is gradually being replaced by SMD and more advanced COB (Chip on Board) packaging in the high-end display field. However, DIP packaging still maintains competitive advantages in specific outdoor application scenarios requiring high brightness and high reliability.

In the future, LED packaging technology will develop towards higher efficiency, higher density, smaller size, and greater intelligence. Both DIP and SMD are continuously optimizing their structures and materials to meet growing market demands. As an industry-leading brand, Kingaurora continues to invest in research and development to promote innovation and progress in LED packaging technology.

3th Building,Gaosite Zone Pingshan

New District, Shenzhen

sevice88@kingaurora.com

3th Building,Gaosite Zone Pingshan

New District, Shenzhen